Phone number:0086-0577-61731588

Fax:0086-0577-61731588

Cell phone:+86 18072180777

Wechat:+86 18072180777

Website:www.china-relay.com

Zhiguang Industrial Zone, Liu Town, Yueqing, Zhejiang, China

Usage

DL-30 series current relays, used as starting elements in overload and short circuit protection lines for motors, transformers and transmission lines.

Structure and principle

1. The relay is electromagnetic and operates instantaneously. The magnetic system has two coils, the head of which is connected to the base terminal.

2. The calibration and rating of the name brand of the relay For current relays are coil in series (in amperes). By rotating the pointer on the dial to change the reaction moment of the hairspring, the operating value of the relay can be changed.

3. Relay operation: When the current rises to or exceeds the setting value, the relay will operate, and the moving closing contact closes, while the moving breaking contact disconnects.When the current drops to 0.8 times setting value, the relay returns, the dynamic closing contact disconnects, and the dynamic breaking contact closes.

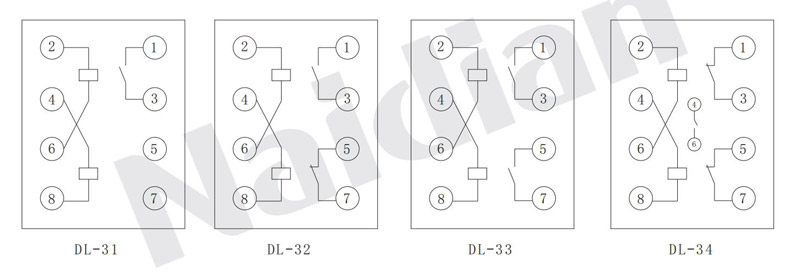

4. See Figure 1 for the internal wiring diagram of the relay

Technical data

1. The number of contacts is shown in Table 1

Table 1

|

Model |

NO. Of Contact |

|

|

Move together |

Move off |

|

|

DL-31 |

1 |

|

|

DL-32 |

1 |

1 |

|

DL-33 |

2 |

1 |

|

DL-34 |

1 |

2 |

2. According to the range of setting value, the operation error of each setting value is no more than +6%, as shown in Table 2.

3. Limit error of relay calibration shall not be more than 6%.

4. The variation of the action value should not be more than 6%

Variation = (Max action value - min action value/average of five actions) x 100%

5. For dl-31,32, 34 current relay, the return coefficient shall not be less than 0.8, and the maximum setting current shall not be less than 0.7 for 200A.

6. Action time

6.1 When the action value is 1.1 times, the action time shall not be greater than 0.12s;At 2 times the action value, the action time is no more than 0.04s.

7. Overcurrent capacity: when the coils are connected in series and rise uniformly from the setting value to the maximum current listed in Table 3, the relay should not vibrate to make the moving and closing contact not work.After five times, the relay can still meet the requirements of this technical condition.

8. Overcurrent: when the setting value of the relay is added 1.75 times or higher, the moving contact of the relay shall close without jitter.

Table 2

|

Model |

Maximum setting current(A) |

Rated Current(A) |

Long term permissible current(A) |

Current setting range(A) |

Current action(A) |

|||

|

Coil in series |

Coil in parallel |

Coil in series |

Coil in parallel |

Coil in series |

Coil in parallel |

|||

|

< |

0 . 0064 |

|

|

|

|

Just a little scale |

0 . 0032 |

0 . 0064 |

|

< |

0 . 01 |

0 . 02 |

0 . 04 |

0 . 02 |

0 . 04 |

0 . 0025 - 0 . 01 |

0 . 0025 - 0 . 005 |

0 . 005 - 0 . 001 |

|

< |

0 . 05 |

0 . 08 |

0 . 16 |

0 . 08 |

0 . 16 |

0 . 0125 - 0 . 05 |

0 . 0125 - 0 . 025 |

0 . 025 - 0 . 05 |

|

DL- 31 |

0 . 2 |

0 . 3 |

0 . 6 |

0 . 3 |

0 . 6 |

0 . 05 - 0 . 2 |

0 . 05 - 0 . 1 |

0 . 1 - 0 . 2 |

|

< |

0 . 6 |

1 |

2 |

1 |

2 |

0 . 15 - 0 . 6 |

0 . 15 - 0 . 3 |

0 . 3 - 0 . 6 |

|

|

2 |

3 |

6 |

4 |

8 |

0 . 5 - 2 |

0 . 5 - 1 |

1 - 2 |

|

DL- 32 |

6 |

6 |

12 |

6 |

12 |

1 . 5 - 6 |

1 . 5 - 3 |

3 - 6 |

|

|

10 |

10 |

20 |

10 |

20 |

2 . 5 - 10 |

2 . 5 - 5 |

5 - 10 |

|

DL- 33 |

15 |

10 |

20 |

15 |

30 |

3 . 75 - 15 |

3 . 75 - 7 . 5 |

7 . 5 - 15 |

|

|

20 |

10 |

20 |

15 |

30 |

5 - 20 |

5 - 10 |

10 - 20 |

|

|

50 |

15 |

30 |

20 |

40 |

12 . 5 - 50 |

12 . 5 - 25 |

25 - 50 |

|

|

100 |

15 |

30 |

20 |

40 |

25 - 100 |

25 - 50 |

50 - 100 |

|

DL- 34 |

200 |

15 |

30 |

20 |

40 |

50 - 200 |

50 - 100 |

100 - 200 |

Table 3

|

Model |

Maximum setting current(A) |

Maximum test current(A) |

|

DL- 31 DL- 32 DL- 33 DL- 34 |

0 . 0049 |

0 . 025 |

|

0 . 0064 |

0 . 032 |

|

|

0 . 01 |

0 . 05 |

|

|

0 . 05 |

0 . 025 |

|

|

0 . 2 |

1 |

|

|

0 . 6 |

3 |

|

|

2 |

10 |

|

|

6 |

30 |

|

|

10 |

50 |

|

|

15 |

75 |

|

|

20 |

100 |

|

|

100 |

100 |

|

|

200 |

100 |

|

|

200 |

200 |

9. When there is no external collision and vibration, when the working current at each setting position (except the first point) of the relay is 0.6, its dynamic breaking contact should close the circuit reliably.

10. In operation and return current: the moving system of the relay should not be stalled in the middle position.

11. In the surrounding air relative humidity is not greater than 85%, the relay circuit of the shell (shell of conductive metal part) of the insulation resistance, using the 500 v megohmmeter, measure shall be not less than 300 m Ω.

12. The insulation of the conductive part of the relay to the housing (non-conductive metal part of the housing) can withstand a test lasting 1min at 50Hz ac voltage of 2kV.

13. Contact disconnection capacity: When the voltage is no more than 250V and the current is no more than 2A, the disconnection power of the contact is 50W in the DC circuit with inductive load (time constant is no more than 5X10s) and 250VA in the AC circuit.

14. Power consumption

At the minimum setting value, the power consumed by the relay coils shall not exceed the data in Table 4.

Use and maintenance

1. Relay before use, need to take the shell, pull out the machine, check whether the transport of damage, such as moving encounter magnetic board, hair spring into the circle, dynamic friction on the shaft card and so on, therefore, will the pointer to the relay setting in the first a fixed point on the moving system with the hand to live the magnetic plate rotation, and then let go, movable system should turn back to its original position until the stop, and then make the necessary adjustment and setting.

2. When the relay is readjusted, it must ensure that:

2.1 The axial activity of the movable system is between 0.15-0.3min.

2.2 The air gap between the moving plate and the magnetic pole shall ensure that the moving plate and the magnetic plate shall not collide under any specified working conditions of the relay.

2.3 For relays with moving-closing contact and moving-breaking contact, bridge contact shall not contact moving-closing contact and moving-breaking contact simultaneously.

2.4 When the pointer rotates from the first scale value to the final scale value, the rings of the hairspring do not touch.

2.5 When the relay operates, the bridge contact shall slide (tolerance +1mm) on the center line of the static contact and move.The total air gap of static contact is not less than 2mm.

2.6 The distance between the stationary contact and the limiting piece shall not be greater than 0.3mm.

2.7 When adjusting the operation value of the relay, the adjustment of the minimum setting value is mainly to change the reaction force of the hairspring, and the adjustment of the maximum setting value is mainly to change the air gap between the moving plate and the magnetic plate, etc.

2.8 The relay shaft and bearing shall not be lubricated.

2.9 It is not allowed to clean the contact with sandpaper or other rough materials. It is advisable to clean the contact with a sharp blade or clean fine grindstone, and then wipe it with a clean, soft cloth to avoid touching the contact with fingers.

Table 4

|

Model |

Max setting value(A) |

Mini setting value(A) |

Power consumption at minimum setting value(A) |

|

DL- 30 |

0 . 0064 |

0 . 0064( Just a little scale) |

|

|

0 . 01 |

0 . 0025 |

0 . 4 |

|

|

0 . 05 |

0 . 0125 |

0 . 4 |

|

|

0 . 2 |

0 . 05 |

0 . 55 |

|

|

0 . 6 |

0 . 15 |

0 . 55 |

|

|

2 |

0 . 5 |

0 . 55 |

|

|

6 |

1 . 5 |

0 . 55 |

|

|

10 |

2 . 5 |

0 . 8 |

|

|

15 |

3 . 75 |

0 . 8 |

|

|

20 |

5 |

0 . 8 |

|

|

50 |

12 . 5 |

6 |

|

|

100 |

25 |

20 |

|

|

200 |

30 |

|

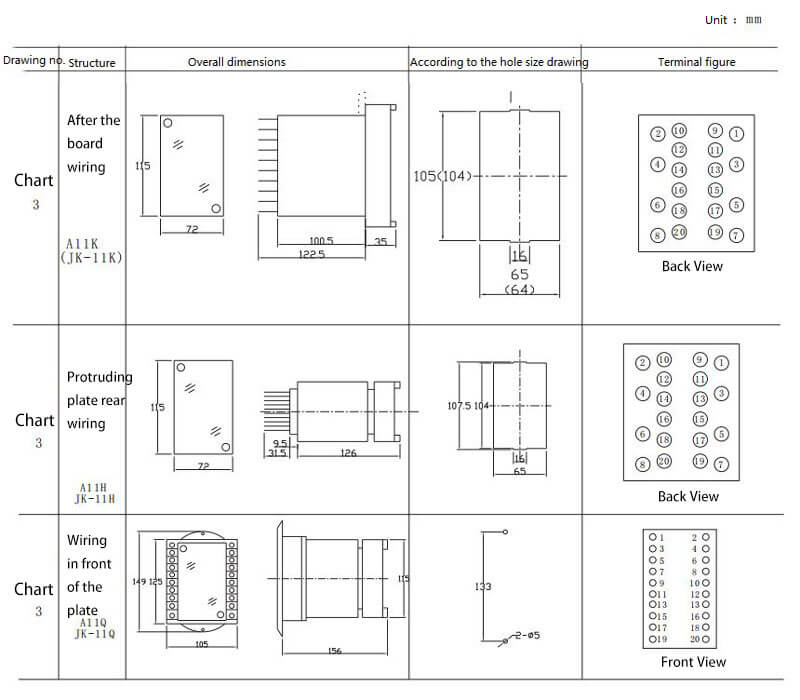

Dimensions and opening dimensions

The shell structure, outline and installation hole size of A11K,A11H and A11Q of this relay are shown in Figure 3 attached to page 288 of this manual.

Message feedback

News Center

Naidian Group is an electronic timer manufacturer and digital timer supplier, providing high-power relays, electronic time relays, digital timer relays, DC to AC solid state relays, and digital display timer relay knowledge popularization.

On February 26, the production of NPOWER Group resumed. The director and manager of our company personall...

An AC contactor is an electromagnetically controlled device that safely and reliably switches high-power ...

A time relay is an electrical control device that introduces a preset time delay to switch circuits, with...

Motor controllers provide comprehensive protection—including overload, short-circuit, phase loss, voltage...

GET A QUOTE