Phone number:0086-0577-61731588

Fax:0086-0577-61731588

Cell phone:+86 18072180777

Wechat:+86 18072180777

Website:www.china-relay.com

Zhiguang Industrial Zone, Liu Town, Yueqing, Zhejiang, China

Protected contact capacity: AC250V/7A, AC380V/5A,

contact life ≥10 5 times.

Overvoltage protection: when the working voltage exceeds

the overvoltage setting value, the

operation time is ≤10S.

Undervoltage protection: when the working voltage is lower

than the set value of undervoltage,

the operation time is ≤10S.

Off-phase protection: when the three-phase current,

arbitrary - phase no current,

the action time ≤2S.

Lock-in protection: when the power current reaches 5 times

of the rated current or above,

the operation time is ≤1S.

Dc4-20ma current output accuracy: 0.3% (20mA corresponds

to twice the set value)

Current display accuracy ≤1.5%.

Product overview

Microcomputer intelligent monitoring motor protector (referred to as monitor), is the company's scientific and technological personnel according to the market needs, adopt user Suggestions in the support of scientific research units to assist, combined with the application principle of single chip computer, the use of foreign new PIC single chip microcomputer, compared with similar products, the technology has gone up a level.It is convenient to digital, intelligent, networked, site monitoring, total anti-interference ability, high precision, stable and reliable work, design the end phase, overload, locked-rotor, short circuit, owe flow, overvoltage, undervoltage, electric leakage, three-phase imbalance protection, and has a current digital display, such as monitoring, intelligent, and other functions, with M type has a DC4-20 a analog signal output, can be directly with the secondary instrument used in industry or computer system interface, with T can monitor remote communication interface between RS485 and RS232 and PC machine, network monitoring system composed of PLC,The system can modify the parameters of the monitor protection and monitor the running state in time, remotely control the start and stop operation of the motor, and inquire the historical data, etc. It is the most ideal electric motor protection product at present.Widely used in metallurgy, chemical industry, textile, petroleum, mining, cement and other automation industries.

The main features

1. EPROM storage technology is adopted to realize parameter electrical setting. After power is dropped, set parameters are thrown to save, and no setting is required.

2, the application of computer and digital processing technology, so that the measurement accuracy is high, good linearity, fault resolution accurate and reliable, anti-interference ability is strong, and has the diagnosis function.

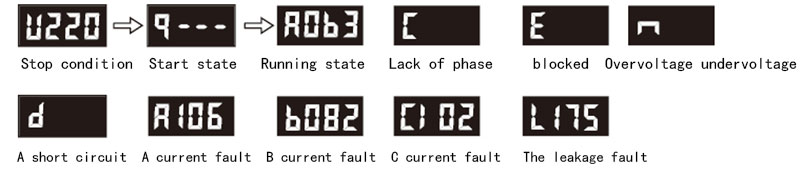

3. The monitor adopts LED display or LCD display for various fault operation status.

4, equipped with RS485 serial digital interface, convenient for digital communication with upper computer (PC).Support modBus-RTU,PROFI Bus-DP protocol.

5. With dc4-20MA analog signal output function, it can be directly connected with industrial secondary instruments or computer systems.

6. Multi-purpose machine can replace ammeter, voltmeter, thermal relay, current transformer, time relay and leakage relay, etc.

7. Easy to install, plate type, guide type, device type installation, can be installed interchangeably with JR16, JR36 and other thermal relays, or can be installed on the guide

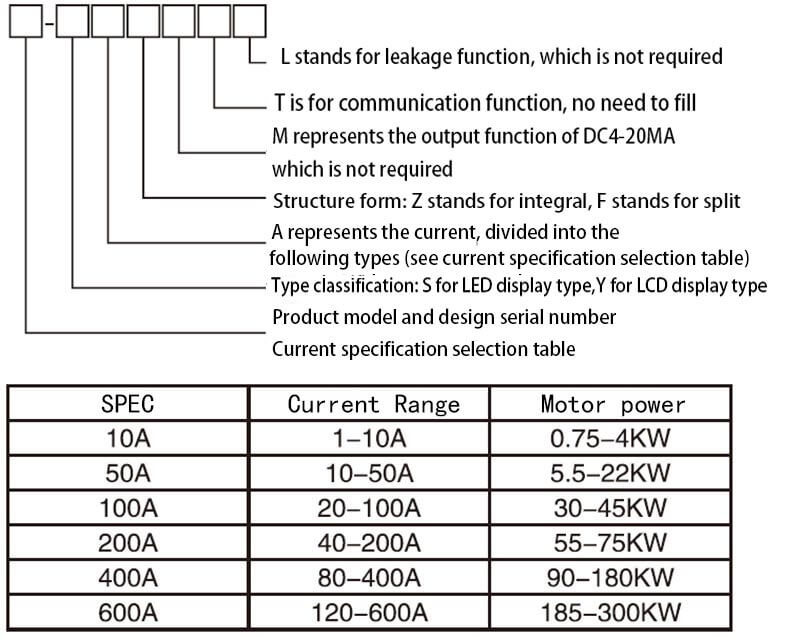

Model and Specification

Description of selection:

Example 1: NDD3-S 50AZML AC220V

For LED display, current specification 10-50A, suitable for 5.5-22KW motor power, integral, with analog dc4-20MA output, with leakage protection function, working voltage AC220V

Example 2: NDD3-Y 100AFTL AC380V

The main function

1. Protection function: overload, lock-in, three-phase unbalance, phase break, over-voltage, under-voltage, under-current, leakage, grounding, short-circuit, line protection and other fault protection.The undercurrent function can be used to prevent the pump motor from burning out when the pump motor is idling. It can also be used to alarm or trip when the pump motor is running under current.

2. Setting function: It can set rated current, starting time, over-voltage value, under-voltage value, over-flow operation time, under-load value, leakage current value, communication address, etc.

3. Display function: display working voltage when powered on;The three-phase current values of A, B and C are displayed in the cycle during detection.Memory display of overcurrent, undercurrent, overvoltage and undervoltage values in the protection state, prompt display of various fault characters.

4. communication function: through the RS485 digital interface, the realization of information transmission, a platform machine (PC) can be connected to 255 protectors, and each motor parameters can be set, start and stop operation, convenient for automatic management.

5. DC4-20ma analog signal output function.

Operating conditions

1. No more than 2500 meters above sea level.

2. Ambient temperature: -30℃-+65℃

3. air relative humidity: at +25℃ not more than 85%, the internal monitor is not suitable for frost, ice.

4. Atmospheric conditions: there is no explosive hazard medium, and no corrosive metal, insulator and conductive dust.

5. Where there is no rain or snow.

6. Where there is no violent vibration or impact.

7. 380, 660VAC three-phase asynchronous motor, feeder circuit protection.

8. Rated working voltage of the monitor: AV220V, AV380V,50HZ allowable deviation ±20%.(Other voltage classes can be customized)

Key description and operation method

1. Setting instructions

Setting key: When the motor is not running, press this key to enter the protection parameter setting state.

Shift key: Select the set bit in the set state (flicker).

Data key: modify the flashing word. When the motor is not running, continue to press this key to enter the normal state.

Reset key: After parameter setting, press this key to save setting parameters and put them into the normal monitoring operation state.If the protection is in operation, press the reset key again to restore the normal monitoring state.

2. Run and display

LED display or LCD display, when the monitor is connected to the working power supply, the voltage value, such as U220, can be used as the voltage value of the back three voltmeter, the monitor can be used as the ammeter function to circulate the three-phase current operation when the rated current is running.

3. Setting of protection parameters

In the start and run elbow of electric motor, press the set key is invalid.Press the "set" key to select the setting type, press the "Shift" key in turn to select the data shift and press the "data" key to modify the data. After setting a certain parameter, press the "Set" key again to enter the next setting state until the end.After the parameters are set, press the reset key to exit the setting state and display the voltage value, such as U220

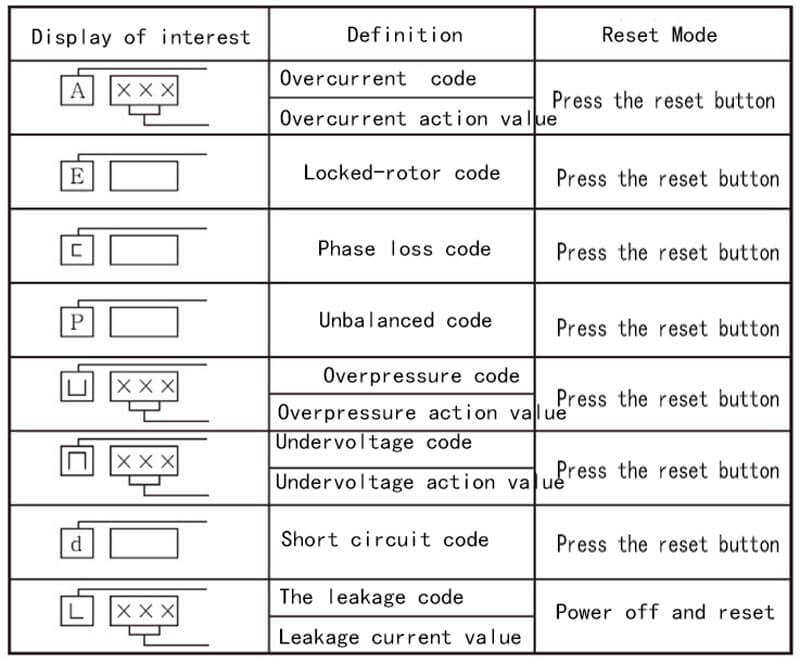

4. Reset mode

Key reset or power reset

Key reset or power reset

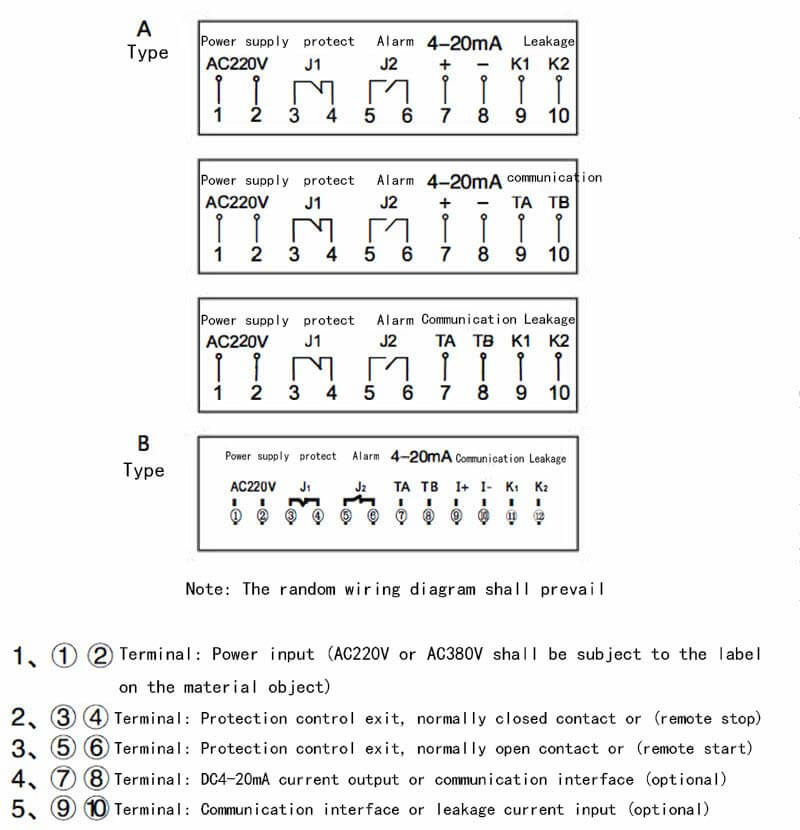

A type

B Type

1. Operating instructions

|

Operating sequence |

Display of interest |

Code definition |

Set introduction |

|

The first time set key |

|

Rated current code |

Units: A |

|

Current setting value |

|||

|

The second time set key |

|

Start time code |

Scope: 1-99 |

|

Start time set value |

|||

|

The Third time set key |

|

Over current time code |

0-999 |

|

Over current time parameter |

|||

|

The fourth time set key |

|

Underload current code |

Units: A |

|

Underload current setting value |

|||

|

The fifth time set key |

|

Over voltage setting |

Units: V |

|

The sixth time set key |

|

Undervoltage setting |

Units: V |

|

The seventh time set key |

|

Auxiliary function setting |

Scope: 1-999S |

|

The eighth time set key |

|

Leakage current code |

Scope: 1-999mA |

|

Current setting value |

|||

|

The ninth time set key |

|

Mail address code |

Scope:0-255 |

|

Mail address set value |

|||

|

The tenth time set key |

The voltage display |

Return |

|

2. Fault code display

LCD panel schematic diagram and operation instructions

1、Operating Instructions

|

Operating sequence |

Display of interest |

Code definition |

Set introduction |

|

The voltage display |

|

|

|

|

|

|||

|

The first time set key |

|

Rated current code |

Units: A |

|

Current setting value |

|||

|

The second time set key |

|

Motor Start time code |

1-99s |

|

Start time set value |

|||

|

The Third time set key |

|

Overcurrent time curve code |

0-999 |

|

Over current time setting value |

|||

|

The fourth time set key |

|

Underload code |

Units: A |

|

Underload setting |

|||

|

The fifth time set key |

|

Overvoltage code |

Units: V |

|

Overvoltage setting |

|||

|

The sixth time set key |

|

Undervoltage code |

Units: V |

|

Undervoltage setting |

|||

|

The seventh time set key |

|

Auxiliary function setting |

0-999S |

|

The eighth time set key |

|

Leakage current code |

1-999mA |

|

Current setting value |

|||

|

The ninth time set key |

|

Mail address code |

0-255 |

|

Mail address set value |

|||

|

The tenth time set key |

The voltage display |

Return |

|

2、Fault code display

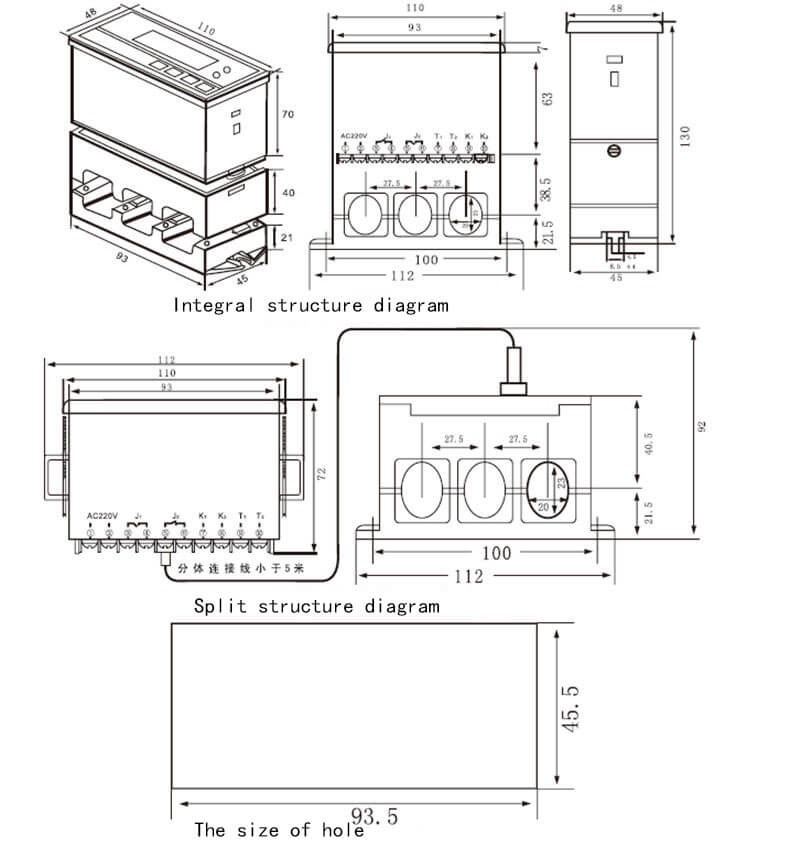

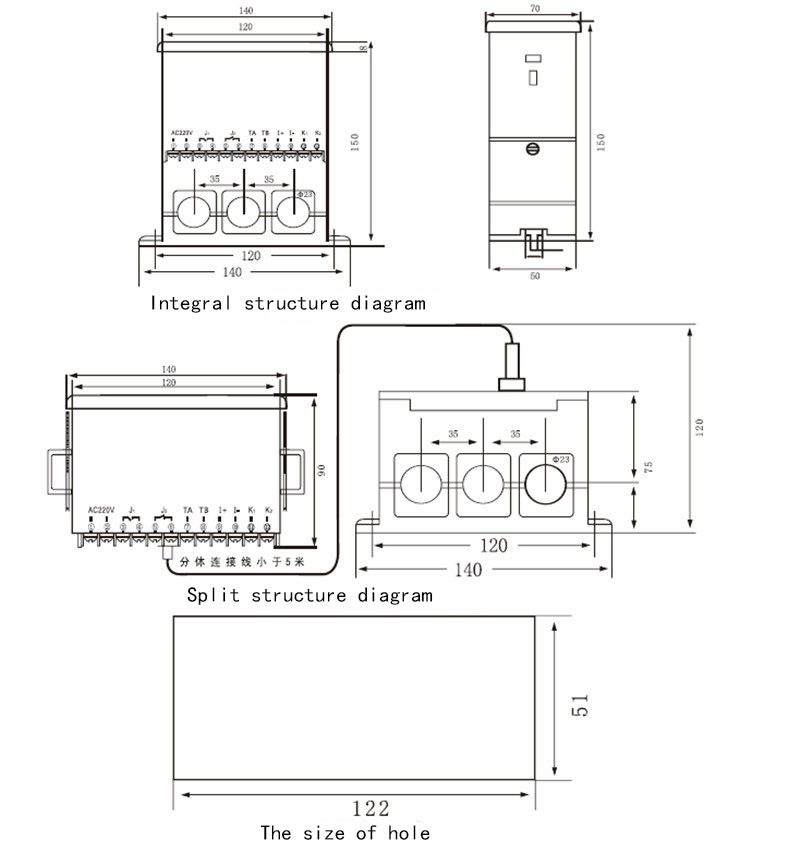

External structure, installation dimension and wiring

Construction and Mounting Dimensions (Type A)

Construction and Mounting dimensions (Type B)

(2)Wiring terminal diagram and instructions for use

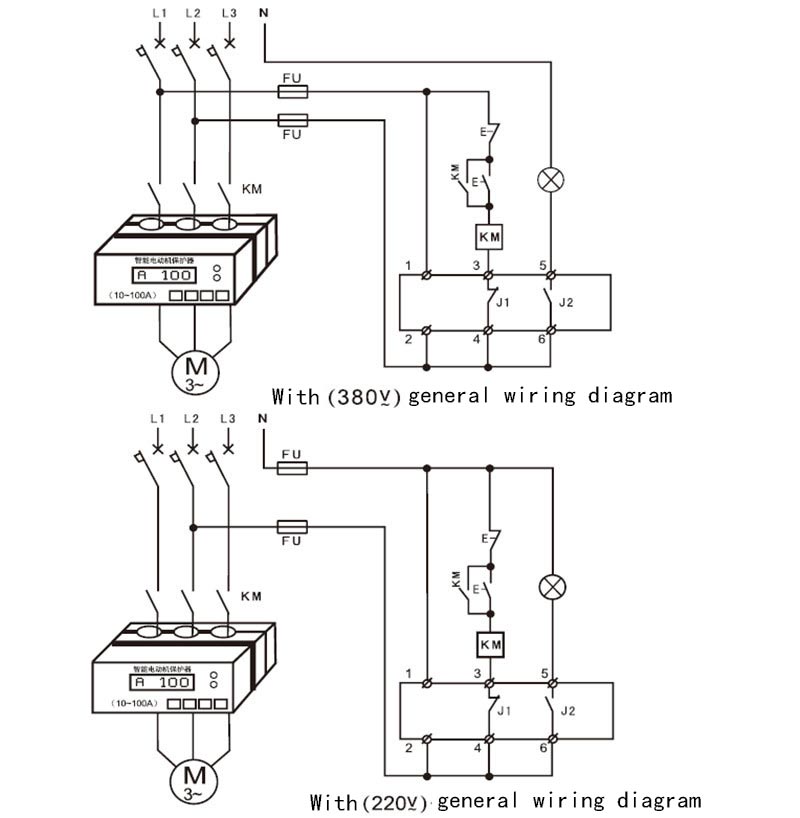

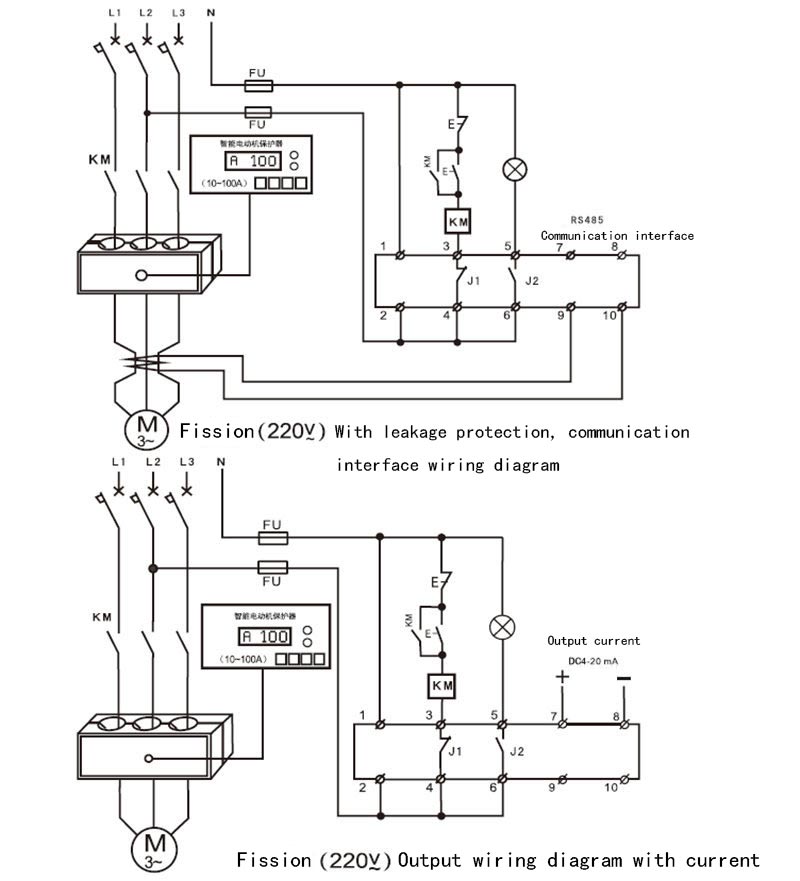

(3)Wiring method

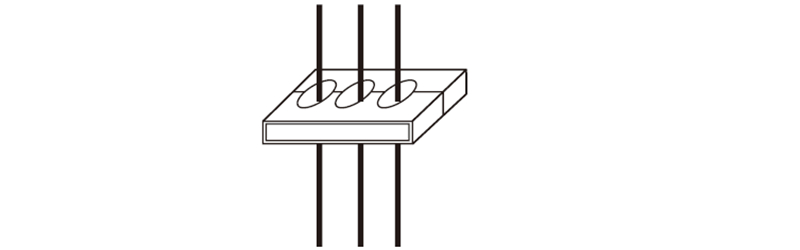

1. One-time connection

Pass through the protector once below 200A

Note: The number of turns needed for the main circuit to pass through the protector is less than 1KW.

The current transformer with a transformer ratio of 5A and above 200A goes through once, and the transformer goes into the protection winding wire with 5 turns twice at the outlet.

2. Secondary wiring

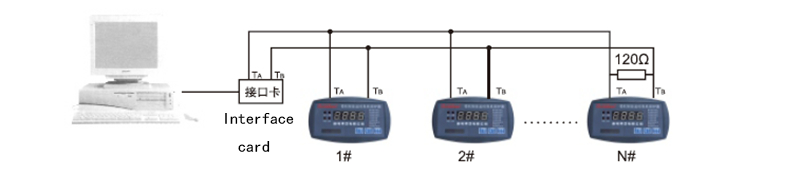

The network connection

1. the introduction of

This system is mainly composed of is located in the central control room of the upper machine (PC) and is located in the control field of computer communication system composed of intelligent monitoring motor protector, software program using the current widely used Delphi language, c + + language and data management systems, and coding, code rate is high, the versatility, portability, reliable operation, installation, debugging convenient.The system adopts RS-485 remote communication interface, supports modBUS-RTU, ProFIbus-DP and other communication protocols, and baud rate is 9600bps.Communication distance up to 1200 meters, the system can simultaneously set, modify, data transmission, start and stop operation, data recording and dynamic display of the motor's working state and parameters for 255 microcomputer intelligent monitoring motor protectors, and striking sound and light alarm for faults.

2. System installation

The communication between the collision monitor and the upper computer should be connected by twisted pair wire with shielding layer.

The system installation shall be done by the users themselves, or our company shall send professional technicians to install and guide the operation on site.

The monitor communication system shall be operated by a technician with microcomputer basic operation skills

Notes:

1. The installation and wiring of the protector shall be correctly connected and in good contact according to the purpose of each wiring terminal.

2. The working power supply of the protector shall be connected to the control circuit. Note that the nominal voltage shall be consistent with the actual voltage.

3. All the protection Settings should be correct, and the Settings of unused options should be abandoned.

4. According to the rated current value of the motor, select the protector of corresponding current specification.

5. For protectors with specifications above 200A, it is not allowed to share with other ammeters when equipped with ammeter. If ammeter display is needed on the equipment site or in the control room, it is better to equip with another AMmeter.

6. The split-type protector is composed of the main display unit and the transformer unit together, and it is a pin-check. Therefore, it should be noted during installation that the main display unit and the transformer unit with different Numbers should not be used together.

7, RS485 communication interface, should be used to connect the twisted pair of the shielding layer, communication port and power port to maintain a certain distance, reduce the source of interference.

8. The external connected device shall match the protector analog value DC4-20mA output.

9. Special zero-sequence current transformer must be equipped when the leakage function is used.

10. Dust removal should be carried out regularly and artificial experiments should be carried out to ensure reliable operation.

Ordering Instructions:

1. The product model, name, working current range, working voltage, quantity, shell structure, installation size, derived code function and so on shall be indicated when ordering.

2. The working voltage of the protector shall be the same as the coil voltage of the AC contactor.

3. When the split-type protector is selected, its standard configuration connection line length is 1

The customer can mark the required length on the contract soil at the time of ordering according to the equipment installation requirements. The maximum length is 5 meters.

4. If the customer needs special specifications, it can be noted in the selection and ordering, and provide detailed technical requirements.

Main technical parameters

1. Protective contact capacity: AC250V/7A, AC380V/5A, contact life ≥10 5 times.

2. Setting range of startup delay time: 1-99s. During startup time, only phase break, overvoltage, undervoltage, leakage and three-phase unbalance are protected.

3. Overvoltage protection: When the working voltage exceeds the overvoltage setting value, the operation time is ≤10S.

4. Undervoltage protection: When the working voltage is lower than the set value of undervoltage, the operation time is ≤10S.

5. Phase break protection: When there is no current in any phase or any phase, the operation time is ≤2S.

6. Three-phase unbalanced protection: when the three-phase current value, any two-phase current difference ratio ≥ the set unbalanced coefficient, and the protection operation time ≤2S.(Factory value set as 50%)

7. Lock-in protection: When the power station current reaches 5 times of the rated current or above, the operation time is ≤1S.

8. Undercurrent protection: The protection elbow can be set according to the actual condition of the load equipment that cannot run in the no-load state, and it can be adjusted to zero when not in use;The monitor will operate in 30S when the current is less than the undercurrent protection setting (set to zero when leaving the factory).

9. Grounding and leakage protection: When the grounding and leakage current is greater than or equal to the set current value, the operation time is ≤ 0.2s.The value of grounding and leakage current can be set by the user according to actual needs (0-999mA).(It has been set at 150mA when leaving the factory)

10. Dc4-20ma current output accuracy: 0.3% (20mA corresponds to twice the set value)

11. Current display accuracy ≤1.5%

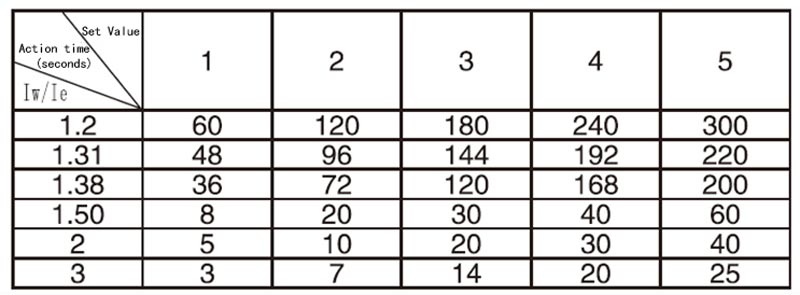

12. Overcurrent protection: The operating time of overcurrent protection can be set by the user. The current multiples corresponding to the serial number of the set value and the characteristics of the operating time of the protection are shown in Table 1 below.(Factory set as 050)

Note: In the table, LW is working current and LE is rated current.

Message feedback

News Center

Naidian Group is an electronic timer manufacturer and digital timer supplier, providing high-power relays, electronic time relays, digital timer relays, DC to AC solid state relays, and digital display timer relay knowledge popularization.

On February 26, the production of NPOWER Group resumed. The director and manager of our company personall...

An AC contactor is an electromagnetically controlled device that safely and reliably switches high-power ...

A time relay is an electrical control device that introduces a preset time delay to switch circuits, with...

Motor controllers provide comprehensive protection—including overload, short-circuit, phase loss, voltage...

GET A QUOTE